Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 132 Author: Site Editor Publish Time: 2023-01-17 Origin: Site

Liquid injection molding (LIM) is the process that molds liquid silicone rubber (LSR) into different silicone components. Traditional forming way of silicone products is compression molding, which is one of the cheapest and simplest molding methods and widely used in rubber industries. But with the higher requirements on the quality and production efficiency, LSR injection molding is developed. Now LSR injection molding process has been highly recognized by rubber parts manufacturers, due to its finished products with superior accuracy, mechanical properties, durability and flexibility on coloring or transparency. In addition, liquid injection molding process can realize high level of automation.

The popularity of liquid injection molding process can also be attributed to the unique properties of liquid silicone material. Liquid silicone is platinum cured silicone, which can contact with food or skin safely. In addition, LSR can resist to temperature ranging from -60°C to +250°C. It is also flame-retardant, electric insulating, and with excellent tensile strength, tear strength and elongation.

Liquid injection molding process can be classified into four types, including

Liquid Injection Molding by injection machine, feeding material automatically

LSR Injection Molding by compression machine, feeding material automatically

LSR Transfer Molding by compression machine, feeding liquid silicone material by manipulator

LSR Transfer Molding by compression machine, feeding LSR manually

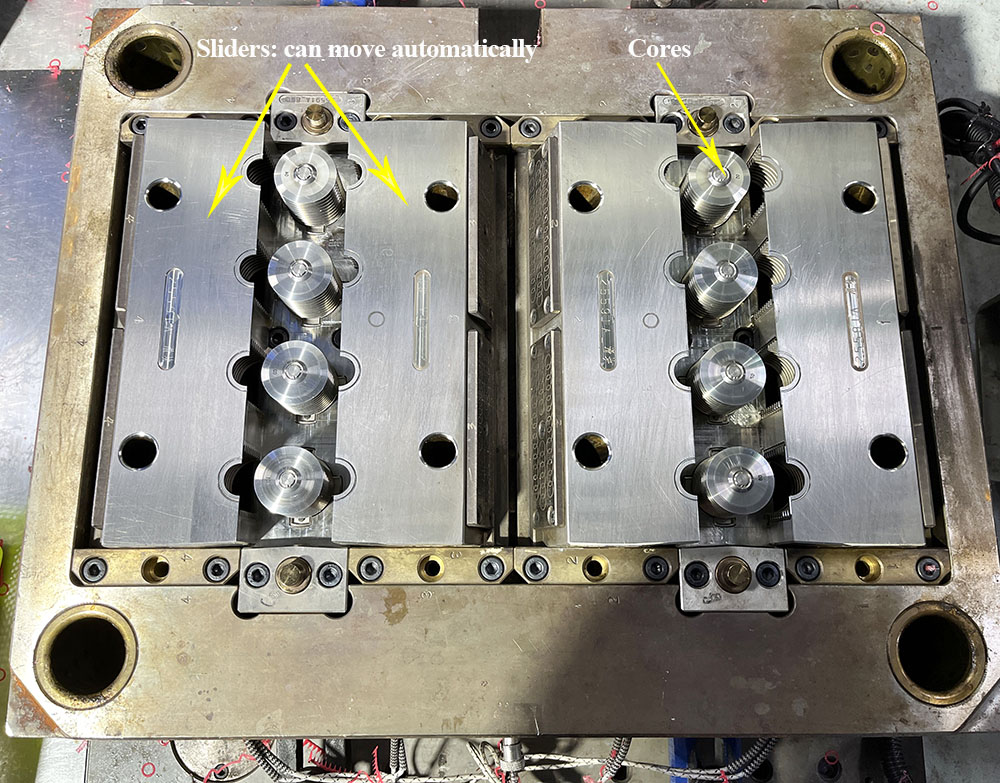

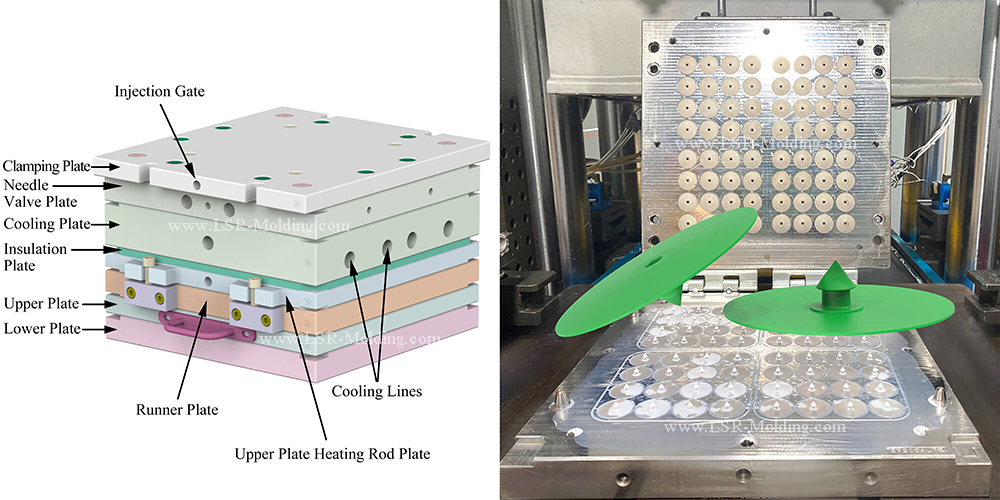

The most precise forming way is liquid injection molding by injection machine. The LSR mold is designed with cold runner system and needle valves that are the nozzles with an automatic shut-off valve, to accurately control the amount of injected material into the cavities. The operation process is completely controlled by the injection machine, from automatic material feeding to automatic ejecting/demoulding of finished products. The automatic molding process increases the production efficiency and keeps the products with stable quality and reduce deviation on the dimensions. The liquid injection process offer much flexibility to geometry designing, as it allows automatic sliders or ejectors, and don’t need high heat or pressure to melt the material and cure the part. LSR to plastic overmolding parts can be made by this liquid injection molding process.

Features: high efficiency, high accuracy, high quality, less waste material, more flexibility on part design

Disadvantage: expensive mold cost, suitable for large volume production

The second precise molding way is liquid injection molding by compression machine. Compared with the first type, this LSR mold is without the bottom ejector mold plates, so it is not suitable for complex design with ejector pins or sliders. The injection molding process is through the compression machine which is refitted with a automatic material feeding system. Specific amount of liquid silicone is automatically injected through the needle valve to mold cavities. To avoid curing of material during injection, there is constant cold water around the needle valve, which is also known as cold runner system.

Features: high efficiency, high accuracy, high quality

Disadvantages: only suitable for part with simple design, more waste material

The third liquid injection molding process is much simpler than the above two types of molding process with cold runner. The mold is only with two or three mold plates, without cold runner system, needle valves, and ejector plates, just like a simple compression mold (transfer mold). Feeding liquid silicone to the mold is through a manipulator. The manipulator can place LSR to the mold cavities more evenly and quickly than manual feeding material. The molds are much cheaper than the LSR injection molds with cold runner, but the accuracy is not good as injection molds. For the liquid silicone parts with extremely tight tolerance or complex design, this compression molding is not recommended.

Features: cheap, more precise than traditional compression molded part

Disadvantages: more waste material, not suitable for complex design

The forth liquid injection molding process is similar to the third one, a compression mold, but liquid silicone is fed to cavities manually. So it is more labor costing. Manual feeding material can not be so precise as that by machine.

Features: cheap, more precise than traditional compression molded part

Disadvantages: more waste material, not suitable for complex design

Contact Us / Product Inquire / Liquid Injection Molding / LSR Molding / Article Inquire / FAQ / Download / Sign In / Register / Gallery / China Hot Products / Hot Products / Liquid Silicone Rubber Molding / Customized service / Request Quote / LSR Mold Design Guide / Liquid Silicone Rubber / Liquid Silicone Rubber Molding / Food Grade Liquid Silicone Rubber / Medical Grade Liquid Silicone Rubber / LSR Seal / Expo News / Industry News / Liquid Injection Molding - Better Silicone Project News / Silicone Materail Certifications / Silicone Umbrella Valves Drawing