Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 219 Author: Site Editor Publish Time: 2022-10-19 Origin: Site

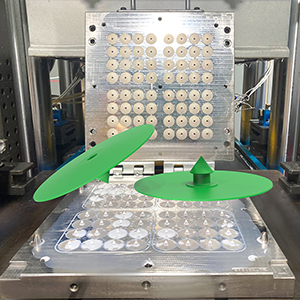

Liquid Silicone Rubber Transfer Molding, also called Converted Liquid Silicone Injection Mold & Converted LSR mold, is one types of liquid silicone rubber molded process, which is molded by compression & press machines in aim to save liquid silicone injection mold cost, and also save sample- & mold-making time.

Why Liquid Silicone Transfer Molding also called converted liquid injection molding?

Liquid silicone transfer molding take full advantage of liquid injection mold's cold-runner systems in aim to produce stable high-quality liquid silicone rubber products or parts.

Liquid Silicone Transfer Molding Main Advantages

1. Much cheaper than liquid injection mold. The cost of liquid silicone transfer molding is almost exactly the same as rubber compression mold.

2. Save liquid silicone rubber sample making time. Generally, liquid silicone injection mold need 30+ days or 45 days, liquid silicone transfer molding need about 7-15 days.

3. Multiple cavities, like rubber compression mold, thus high yield.

4. Low mold tool maintenance costs.

5. Low machines Cost.

Liquid Silicone Transfer Molding Main Disadvantages

1. Some companies also called liquid silicone injection molding, however, liquid silicone transfer molding is not suitable to produce too thick silicone parts, because vacuumizing is not available in transfer molding. Incomplete venting will cause short shot, and dent defects on silicone products.

2. Limited by the rubber compression machine, liquid silicone transfer molding cannot manufacture high-accuracy silicone parts. First, accuracy of transfer mold is not good as LSR injection mold with cold runner system. In addition, compression machine is the common machine used for transfer molding production. The control of material feeding, molding pressure, temperature, and curing time is not as excellent as liquid silicone injection machine.

3. Complex & complicated silicone designs also not suitable to produce by liquid silicone transfer mold.

Liquid silicone transfer mold can not be with sliders, as the mold lifetime is short, and it affect quality of molded parts. Most sliders in transfer mold are moved and assembled manually, while the sliders in LSR injection mold move automatically and controlled by machine. So misalignment of parting lines, and big flashing always happen in transfer molding with sliders.

4. Molding material may be wasted, thus higher material expense. Requires removal of silicone flash.

High production efficiency and stable product quality is hoped in silicone product area.There are two processes that can satisfy the needs of customers. Liquid silicone injection molding and liquid silicone transfer molding, with using the same raw material, but have different performances. From cases to know their pros and cons below.

Liquid Silicone Injection Molding

Liquid silicone injection molding is a high level process to manufacture silicone product with A+B double groups raw material (liquid).

How to show the high level of liquid silicone injection molding? Extreme automation and high precision. Liquid injection molding is different from silicone compression molding, it perform very well at over molding between silicone and plastic because of silicone injection molding use platinum curing system, its curing temperature can be 120 ~ 150 Degree C.

Liquid Silicone Transfer Molding

Liquid silicone transfer molding is also named as converted liquid silicone compression molding, similar to the liquid silicone injection molding material feeding system, raw material is liquid silicone and inject raw material from sprue into mold cavities automatically. Liquid silicone transfer molding can fully use the existing compression silicone rubber molding machine, realize the intelligent linkage with the flat vulcanizer, automatically control the amount of injected silicone material, and use the silicone compression mold to produce liquid silicone products, shorten processing time of solid silicone compression molding, greatly improve its production rates and decrease its production costs in higher volume projects.

There are two injection methods of silicone:

1). Manual liquid silicone material feeding: the mold is opened, the material is accurately measured by the machine, and the silicone material is manually put into the mold cavities through the material feeding hose through the gun head, and then the mold is closed and hot-pressed. But this material feeding method cannot improve production rates, just improves product quality.

2). Automatically liquid silicone material feeding: after the high pressure of mold clamping is completed, the stored material accurately measured by the machine is directly injected into the mold cavities through the hose and the cold runner plate to realize the injection and placing silicone material. After the product is hot-pressed in the mold, it slides out of the mold top out the product. This material feeding method is similar to liquid silicone injection molding, with high production efficiency and stable material feeding volume - stable quality.

In other words, for simple design, liquid silicone transfer molding is nearly a low cost injection molding process.

Which is the Better Choice for Your Silicone Product?

Similar silicone injection system causes better quality and stable quality. Exactly the silicone product molded by liquid silicone injection molding and liquid silicone transfer molding is made from liquid silicone, which is safe, beautiful, especially used in medical area, food contact area, baby product area, etc.

As mentioned above, automation improves production efficiency and quality stability. But they performs differently in some factors.

Why liquid silicone transfer molding is a low cost liquid silicone injection molding?

1) Automatically inject liquid silicone, same as injection moulders - decrease manual process, increase quality stability;

2) Short silicone curing/vulcanizing time, similar to injection mold tooling, the curing time is 1/4-1/3 of that of compression molding - high production efficiency;

3) More mold cavities than lsr molding, with the same silicone product, the mold cavities of injection molding is limited of the press and silicone injection molding machine;

4) Simplified mold design, shorter mold production cycle than lsr injection molding, lower mold cost.

Therefore, the unit price of silicone product is similar, even if the automation of liquid silicone transfer molding is lower than injection molding.

Although liquid silicone transfer molding/converted liquid silicone compression molding is a cheaper choice for manufacturing good quality silicone product, it cannot replace injection molding.

Liquid silicone injection molding perform very good at high precision, and complicated design of silicone product, but liquid silicone transfer molding cannot achieve that because the limit of the compression machine.

Precision Comparison:

Liquid Silicone Injection Mold > Liquid Silicone Transfer Mold > Silicone Compression Mold

Why liquid silicone transfer molding cannot be used for complex silicone product?

Liquid silicone transfer mold is a simplified liquid silicone injection mold, lack of vacuum system besides simplified mold templates causes air traps in silicone product. So, liquid silicone transfer molding is just good at simple design and not too thick silicone product.

Here is one silicone o-ring seal below, made from both liquid silicone injection molding and liquid silicone transfer molding:

The liquid silicone seal is beautiful mold by liquid silicone injection molding.

But the perfect seal cannot be molded by liquid silicone transfer molding, vacuum extractor is significant important, but the molding method without.

See the structure of the seal:

There is big differences in wall thickness, height difference, and rib structure difference.

Limited of compression machine and mold templates, the liquid silicone transfer molding is without vacuum system to pull out air from cavities, so that air traps occur (defective product).

All advantages & disadvantages of the two molding methods can be summarized as below:

To sum up, both liquid silicone injection molding and liquid silicone transfer molding can meet the demands of high production efficiency and stable quality.

The major difference is in precision and development costs.

Liquid silicone transfer molding can satisfy the need of general precision, but liquid silicone injection molding is the better choice, if customer hopes high precision silicone product. Liquid silicone transfer molding is better if the silicone product design is simple and customer hopes faster mold production cycle and cheap mold cost.

Contact Us / Product Inquire / Liquid Injection Molding / LSR Molding / Article Inquire / FAQ / Download / Sign In / Register / Gallery / China Hot Products / Hot Products / Liquid Silicone Rubber Molding / Customized service / Request Quote / LSR Mold Design Guide / Liquid Silicone Rubber / Liquid Silicone Rubber Molding / Food Grade Liquid Silicone Rubber / Medical Grade Liquid Silicone Rubber / LSR Seal / Expo News / Industry News / Liquid Injection Molding - Better Silicone Project News / Silicone Materail Certifications / Silicone Umbrella Valves Drawing