Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 153 Author: Site Editor Publish Time: 2020-07-26 Origin: Site

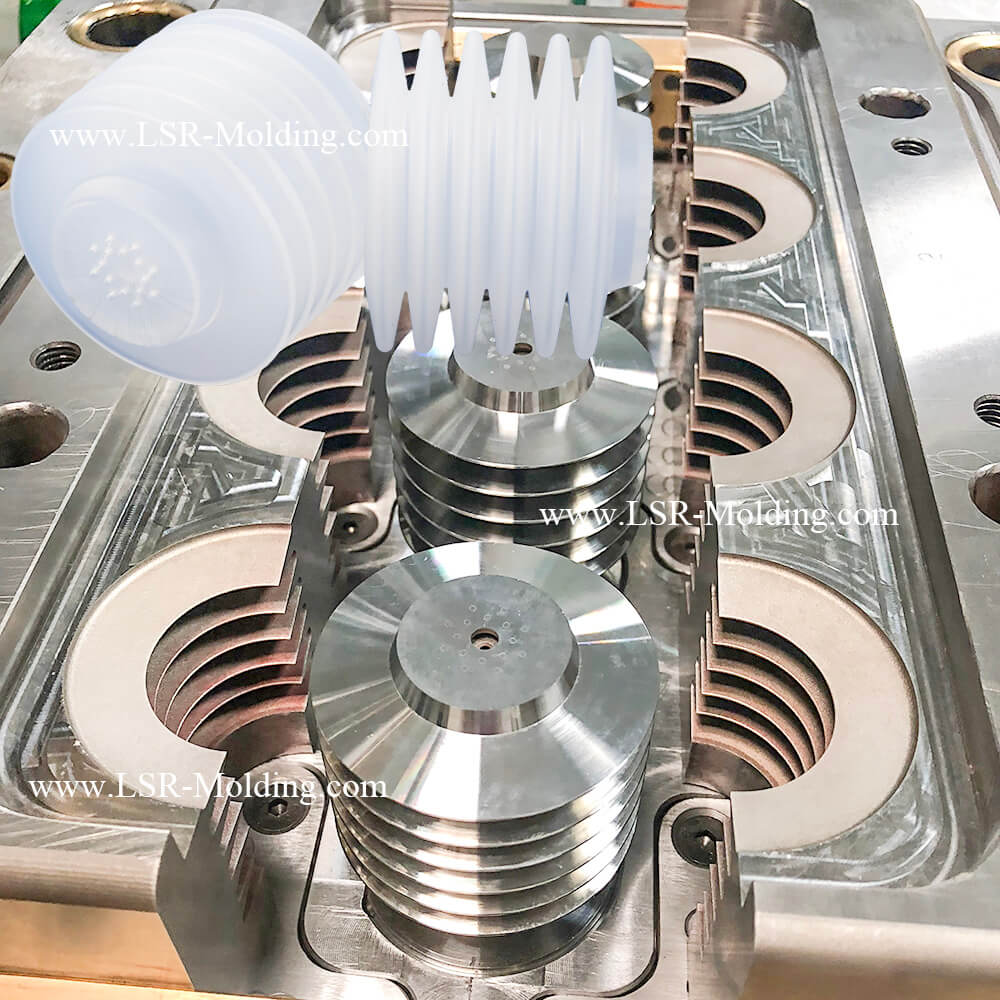

Liquid Silicone Injection Molding (LIM) Process for Complex Geometry

Liquid Silicone Injection Molding (LIM) is an ideal process for many custom parts and components with complex geometry, showing significant advantages over traditional Silicone Rubber Compression Molding and Transfer Injection Molding, in flexible tooling design, excellent liquid silicon rubber properties, high production efficiency & safe closed production environment and tight tolerance/precision, LSR 2-Shot (2K) or LSR Multi-Shot injection molding (also known as LSR overmolding), etc.

When some customers need to customize silicone component with complex geometry, they usually tend to take Liquid Silicon Injection Molding as the first choice. Here, we will take liquid silicone bellows with side holes and undercuts as an example, which is used for sticker label on fruit.

1. Silicon Injection Molding Complex Design- undercut

For silicone bellow with undercut, it’s an important for designers to consider demolding during design process. Engineers need to proceed on manufactuability and moldability on product structure, then achieve feasibility and the easiest demolding during production. The liquid silicone rubber material used for Silicone Injection Molding has excellent physical properties, such as high tensile strength and elongation, etc.

Therefore, For the low undercuts, we can eject component from mold directly without any special mold structure. For many products involving high undercuts, draft angle is usually no need to consider, but tend to choose middle-plate or slider & splits structure for achieving demoulding.

2. Silicone Injection Molding Complex Design- Side Holes

For Silicone Bellows involving side holes, it can be manufactured by either Silicone Rubber Compression Molding or Liquid Silicone Rubber Molding. But the optimal solution is Liquid Injection Molding, which can achieve through holes (flash-less & burrs-free in holes) by designing Kiss Off (K/O) structure for mold. Therefore, through holes can ensure good function of air flow and silicone bellows can work well.

However, if side holes are manufactured by Compression Mold, there will be flash& burrs in the holes and we need to proceed secondary deflashing & deburring. The trimming tools don’t work very well because these holes are tool small. In case that flash & burrs can’t be cleaned out completely, they will affect the functions of Silicone Bellows.

Liquid Silicon Injection Process-Complex Geometry and Complicated Design

Contact Us / Product Inquire / Liquid Injection Molding / LSR Molding / Article Inquire / FAQ / Download / Sign In / Register / Gallery / China Hot Products / Hot Products / Liquid Silicone Rubber Molding / Customized service / Request Quote / LSR Mold Design Guide / Liquid Silicone Rubber / Liquid Silicone Rubber Molding / Food Grade Liquid Silicone Rubber / Medical Grade Liquid Silicone Rubber / LSR Seal / Expo News / Industry News / Liquid Injection Molding - Better Silicone Project News / Silicone Materail Certifications / Silicone Umbrella Valves Drawing