Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 320 Author: Site Editor Publish Time: 2021-06-24 Origin: Site

Why Choose Fluorosilicone Liquid Silicone Rubber (FLSR) for Your Project? ---Fluorined LSR Molding Process

What is Fluorosilicone Liquid Silicone Rubber (FLSR)?

Fluorosilicone Liquid Silicone Rubber also called as FLSR, Fluorined Liquid Silicone Rubber, Fluorined LSR, Fluoro-Liquid Silicone Rubber, and which is two-part materials with a convenient 1:1 mix ratio, like common Liquid Silicone Rubber, pigmentable soft paste composed of fluorosilicone. F-LSR is supplied as solventless, produced by Liquid Injection Molding processes. And the fluorine reacts with polymer chain and be blended typically at 60/40 ratio or a 100 percent fluorosilicone LSR (FLSR) polymer.

Fluoro-Liquid Silicone Rubber (F-LSR) combines the fluid resistance benefits of fluorosilicone rubber with the processing benefits of liquid silicone rubber, and are readily mixed and rapidly heat-cured using standard Liquid Injection Molding equipment. Parts fabricated with F-LSRs can resist extreme heat or cold. FLSR designed for use in harsh environments involving fuel, oil or aggressive fluids, these 100% fluorinated, liquid silicone rubbers combine the fluid resistance of fluorosilicone rubber with the processing ease of liquid silicone rubber.

Fluorosilicone Liquid Silicone Rubber's Properties:

Excellent processing performance

FLSR also is highly resistant to fuels and oils

Fast cure rates

Reduced cycle times

Lower production costs

Good extreme heat or cold resistance

Withstand harsh environments involving fuel, oil or aggressive fluids

The Fluorinated LSR demonstrates good resistance to diverse chemicals and solvents over a temperature range of -63°C to +175°C in immersion conditions, and up to +225°C under dry heat conditions.

The feature of chemical resistance and thermal stability, with longer usage life and can seal more effectively compared with other elastomers

Type | Material | Service | Molding Process | Property |

LSR(Fluorosilicone) | FL 60-9201 Fluoro LSR | LSR Injectiion Molding | Injection Molded | Data Sheet |

LSR(Fluorosilicone) | FLR 3900/40 A/B | LSR Injectiion Molding | Injection Molded | Data Sheet |

Fluorosilicone | ELASTOSIL R 901_40 CN | Compression Molding | Compression Molded | Data Sheet |

Fluoroelastomer | FK7003KB | Compression Molding | Compression Molded | Data Sheet |

Fluoroelastomer | F-70101A | Compression Molding | Compression Molded | Data Sheet |

Fluorosilicone Liquid Silicone Rubber's Mian Applications:

Solvent and chemically resistant molded components

Products used in harsh environments involving fuel, oil or aggressive fluids

Gaskets and membranes for challenging static and dynamic sealing applications

Complex components with strict tolerances

Thin, high-precision coatings

Aerospace areas

Automobile Accessories

Extrusion onto fabrics, belts, wires, and other surfaces

Fluorosilicone LSR vs. Silicone/Why choose Fluorosilicone Liquid Silicone Rubber?

1.Higher Precision and More Stable Design/Quality

Fluorosilicone Liquid silicone Rubber is low viscosity material, which can fluid to fill very thin and tiny space to produce complex shape products. So many complex structure, thin wall thickness products, and the products that need good appearance with good looking parting line, will choose liquid silicone as material and choose liquid injection molding process. choose liquid silicone injection molding process

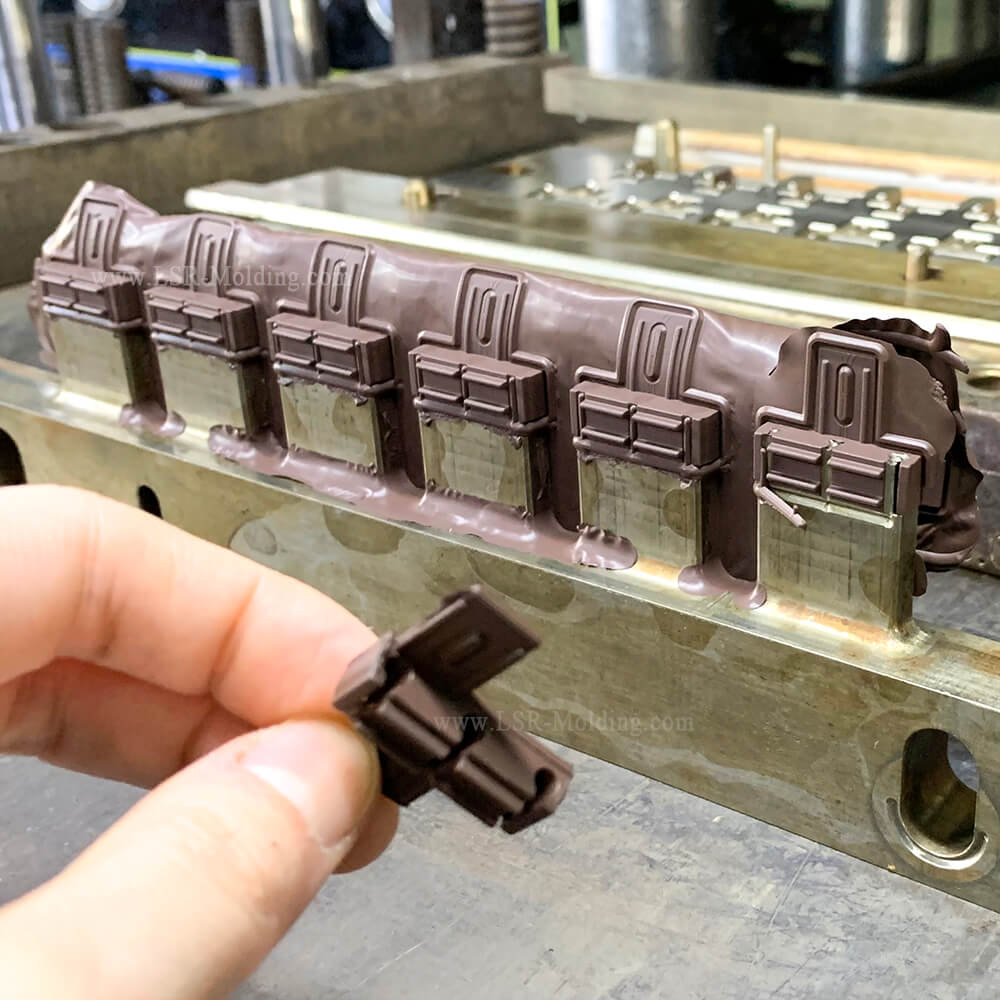

And because Fluorined LSR is pushed into the mold under pressure and liquid silicone keep cool inside the sprue and runner, and the needle valve control the amount of the material into each cavity in certain speed and pressure, so liquid silicone molded parts can achieve +-0.02mm tolerance and with stable design and quality.

What’s more, because vulvanization only occurs inside the hot cavities, so do not have rubber flashing on the products, with good looking parting line and more stable design/quality. High requirement tolerance and quality products will choose Fluorosilicone rather than common silicone as material.

2. Superior Properties Compared to Common Silicone

Wide hardness range of 10 to 80 durometer Shore A

Wide operating temperature

Excellent UV and ozone resistance

Highly resistant to fuels and oils

Excellent electrical insulation

Excellent for outdoor environmental sealing

Good Resistance to extreme heat or cold resistance resistan

3. Higher Production Efficiency

Compression molded Silicone part needs to cut material into a certain size and thickness suitable for molding, and then placed in cavities, and manual demoulding. The whole process is long and curing time is also longer than liquid injection molding.

Fluorined Liquid Silicone Rubber by LSR Injection Molding, when the moulding started, the barrel of the injection machine is extracted from the A and B groups at a ratio of 1:1 and thoroughly mixed automatically and then injected into the mold cavities through a vulcanization screw at a certain speed under certain pressure. And with shorter curing time, the liquid rubber sillicone parts come out in the mold with no or less rubber flashings, which not only save production time but also save trim time. So for large quantity products, liquid silicone rubber injection mold is a better choice. And with the development of economy and technology, liquid injection molding is tending to be completerly automatically.

FLSR parts by Liquid Injection Molding also save time to trim the rubber flashing from the products.

Contact Us / Product Inquire / Liquid Injection Molding / LSR Molding / Article Inquire / FAQ / Download / Sign In / Register / Gallery / China Hot Products / Hot Products / Liquid Silicone Rubber Molding / Customized service / Request Quote / LSR Mold Design Guide / Liquid Silicone Rubber / Liquid Silicone Rubber Molding / Food Grade Liquid Silicone Rubber / Medical Grade Liquid Silicone Rubber / LSR Seal / Expo News / Industry News / Liquid Injection Molding - Better Silicone Project News / Silicone Materail Certifications / Silicone Umbrella Valves Drawing